Welcome to Advanced VSR Technology

Manufacturer / Exporter / Supplier Of Vibration during Welding, VIBRATORY STRESS RELIEF, Custom Electrical Panels

-

Year of Establishment

2011

-

Primary Business

Supplier

-

Number of Employees

1-9

Welcome to Advanced VSR Technology

Manufacturer / Exporter / Supplier Of Vibration during Welding, VIBRATORY STRESS RELIEF, Custom Electrical Panels

Year of Establishment

2011

Primary Business

Supplier

Number of Employees

1-9

Our basic system's features : 3 kW Allen-Bradley motor drive with external heat sink (80% heat dissipation is outside the NEMA 4-grade enclosure) Digital displays of workpiece vibration amplitude, vibrator motor current, vibrator speed RPM Digital speed control increment of 6 RPM 300 - 7500 RPM 3 phase motor with 20:1 adjustable unbalance.

Welding distortion is a common problem: A survey of fabrication shops we conducted in 2015 found that many shops spend between 5 – 10 % of their shop labor time correcting welding distortion. For many years, fabricators have vibrated fabrications during welding, in hopes of reducing distortion, with a mixed range of success. Some manufacturers of vibratory stress relief systems, other than Advanced VSR, have claimed that their standard equipment is suitable for this task. There are a few problems with this recommendation, however, the most important being a safety issue: Using an electrically powered vibrator, which for purposes of safety, must be electrically grounded "earthed", while at the same time welding on metal that is electrically connected or adjacent to the vibrator, poses a risk: A loss of the welding grounded could send the high-amperage welding current thru the electric motor's ground line, which is several times too small to carry it. This could not only cause damage to the motor cable and motor, but also cause a fire to start. Keep in mind that the welder is most likely focusing on the welding, so the smell of ignition from the burning motor cable might not be immediately noticed, since the normal smells and sounds of welding would mask it.

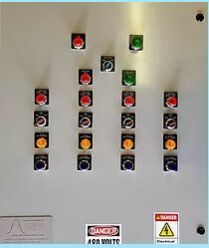

Advanced VSR has decades of experience in designing and building custom electrical panels, which also include the control consoles for our VSR and VDW systems. We also have extensive experience with electric motor protection, which includes rotary electric vibrators. These devices are among the most often overloaded and overheated electric motors in industry. Panels designed to power, control and protect such motors include a designs using solid-state overload relays, pushbuttons and selector switches with gold-flashed contacts, and well laid out cable paths and connectors. Combining these elements result in not only an extremely reliable control panel, but extension of the useful life of the equipment being controlled. Below are just a few examples of the dozens of panels we have designed and built. Components used in these panels include those made by Allen-Bradley, Sprecher & Schuh, ABB, among others. These components can also be selected so to compliment legendary products used in existing facilities.

Share your thoughts with other customers for Advanced VSR Technology

Add Review