Welcome to Beacon Industries, Inc.

Manufacturer / Exporter / Supplier Of Discs, Hubs, Shafts, Compressor Rings, Cases, General Machining

-

Year of Establishment

1948

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Beacon Industries, Inc.

Manufacturer / Exporter / Supplier Of Discs, Hubs, Shafts, Compressor Rings, Cases, General Machining

Year of Establishment

1948

Primary Business

Supplier

Number of Employees

50-99

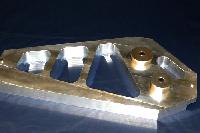

The fan blade is made by shaping molten titanium in a hot press. When removed, each blade skin is welded to a mate, and the hollow cavity in the center is filled with a titanium honeycomb. The turbine disc is made by broaching, which is Beacon’s speciality.

The propeller hub, affixed to the engine's crankshaft, is the critical link between the power producing engine and the movement producing propeller, and is the core of Beacon’s expanding product line.

The shaft connects the turbine to the compressor in an airplane engine, and runs most of the length of the engine. There may be as many as three concentric shafts, rotating at independent speeds, with as many sets of turbines and compressors. Beacon has significant experience building this part as well.

Rings have a lot of importance within an aircraft engine particularly the compressor which consists of a set of rotor blades attached to a rotating disk, followed by stator vanes attached to a stationary ring.

Fan Case of aircraft turbo fan engines is located in the front end of an engine, and surrounds a periphery of fan blades. Beacon has all the necessary equipment and expertise to build such a part as well.

Beacon has also got experience in manufacturing various other components which is what makes it a dominant force in the industry today.

Share your thoughts with other customers for Beacon Industries, Inc.

Add Review