Welcome to Black Bros. Co.

Manufacturer / Exporter / Supplier Of AIR POD PRESS, POWER POD PRESSES, 3D-SMARTPRESS, 22D-650 ADHESIVE SPREADER, 22D-875 GLUE SPREADER

-

Year of Establishment

1882

-

Primary Business

Supplier

Welcome to Black Bros. Co.

Manufacturer / Exporter / Supplier Of AIR POD PRESS, POWER POD PRESSES, 3D-SMARTPRESS, 22D-650 ADHESIVE SPREADER, 22D-875 GLUE SPREADER

Year of Establishment

1882

Primary Business

Supplier

The Black Bros. 22D-650 Adhesive Spreader and Roll Coater is a strong machine built for when your process requires a narrow coating width. The 6.5-inch (165 mm) rolls offer a deeper reservoir with standard machine width ranges from 26″ to 38″ (660 mm to 965 mm). The 650 is part of the 22D family of machines, therefore a large number of options are available along with a substantial standard equipment list. Consider a 22D-650 Spreader or Coater when you want to process small to medium sized components and need special machine features not available on the 775 Spreader and Coater.

The Black Bros. 22D-875 Roll Coater Glue Spreader is one of the most admired models in our line of quality equipment. Our 22D-875 glue spreaders can be found in plants all over the world, still operating reliably over 40 to 50 years on the job. Standard sizes start at 44″ (1118 mm) and run to 74″ (1880 mm) wide. Built to provide service 247, with a heavy duty welded steel frame. Black Bros. 22D-875 glue spreaders can coat the heaviest substrates in the most rugged environments, or use its precision to achieve extreme accuracy of coating weights. The Black Bros. 22D-875 Roll Coater Glue Spreader uses an 8.75-inch diameter (222 mm) coating roll. It is available with a broad range of operator friendly features, and automation options, to match the demands of any operation.

Built on an expanding platform – the only press that grows with your business! In the world of membrane presses, the 3D-SmartPress was engineered to overcome one of the main problems in the industry, machine obsolescence. As a result, Black Bros. has designed a machine with the built-in ability for expansion into an automated pin system.

The Black Bros. Power Pod Press offers customers a low-priced, moderate pressure press. The 28″ (711mm) high opening is designed to laminate one stack of boards at a time (up to 34- 14″ thick panels). Up to 40 PSI of regulated laminating pressure can be developed, adequate for laminating HPL to particleboard or MDF. To keep cost to a minimum, it was designed with a fixed opening. The press is offered in two popular sizes, 4′ x 8′ (1219 mm x 2438 mm) and 5′ x 12′(1524 mm x 3658 mm) designed to meet the needs of the smaller shop, or a larger shop with small to moderate laminating requirements of pattern sized panels.

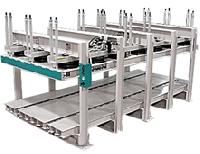

The Black Bros. Air Pod Press uses air operated platen presses that are commonly used for stack-laminating “sandwich-type” assemblies such as flush doors, table tops, furniture parts, insulating panels, etc. Today’s improved close tolerance stock with uniform thickness and surface smoothness eliminates the need for the high pressures previously required to bring face and core stock surfaces into bonding contact. Black Bros. Air Pod Presses apply uniform pressure over the entire platen area for strong, high-quality bonds, and increase production of same size panels compared to one-at-a-time systems. Platen sizes are available from 2′ x 4′ (610 mm x 1219 mm) to 5′ x 12′ (1524 mm x 3658 mm). Presses are available in: end or side loading styles; with manual or motorized height adjustment; 10, 50, and 80 psi (69, 345, and 551 kPa) models. Normally, two or more presses are used to provide continuous production output. For Extra large laminating, such as SIP Panels or Van Trailer, Air Pod Presses can be configured together to create very spacious platen areas. The largest APP built by BBCO to date is a 12′ x 54′ Press.

Share your thoughts with other customers for Black Bros. Co.

Add Review