Welcome to California Brazing & Nevada Heat Treating

Manufacturer / Exporter / Supplier Of Furnace Brazing, Vacuum Aluminum Brazing, Hydrogen Brazing, Turnkey Manufacturing, CNC Machining, Heat Sinks

Welcome to California Brazing & Nevada Heat Treating

Manufacturer / Exporter / Supplier Of Furnace Brazing, Vacuum Aluminum Brazing, Hydrogen Brazing, Turnkey Manufacturing, CNC Machining, Heat Sinks

We Offer Expert Furnace Brazing Services, Specializing in AS9100-certified Aluminum Brazed Assemblies Aerospace Vacuum Furnace Brazing and Hydrogen Brazing As a trusted industry leader in furnace brazing services, California Brazing features fully-equipped facilities to provide superior quality and value while meeting our clients’ unique project demands. With the resources and experience to identify the precise process or cycle for your parts or assemblies, we can accommodate both simple and complex jobs so you get the most from brazing. And we have assembled the people and systems to provide full turnkey manufacturing, including CNC machining, and design verification and analysis. Working with aluminum, copper, ceramic, and stainless steels, we offer an array of brazing alloys, including copper, gold, and other precious and non-precious brazing filler metals. Our brazing services include: vacuum furnace brazing, vacuum aluminum brazing and hydrogen brazing. Some of the characteristics provided by our brazing processes include: Reliability and consistency Precise joining of thin and thick sections Minimal distortion Permanent bonding High strength

Turnkey Manufacturing, Assembly, Testing, and Logistics Services Turnkey Manufacturing Providing precision contract manufacturing solutions California Brazing ensures high quality products with fast transition times from production to market. Our state-of-the-art facilities offer comprehensive services, ranging from prototyping to assembly, testing and supply chain management – all managed in-house as your turnkey manufacturer. Our expert staff consults with each client, gaining a thorough understanding of our customer’s project requirements. With our technical expertise, creativity, and attention to detail, we can solve the most complex, precise aerospace manufacturing challenges, always meeting our clients’ business objectives. Combining our lean manufacturing operations with comprehensive turnkey services, we can help our clients out-pace their competitors while still producing AS9100-quality products. Some of these turnkey operations include, but are not limited to, assembly, prototyping, supply chain management, and production design for better manufacturability at lower costs. Manufacturing high-quality products with quicker turnarounds at reduced costs, we invite you to contact California Brazing to learn more about our comprehensive turn-key services.

Quality and Precision in Aerospace CNC Machining and Turning Services, AS9100 Certification Providing precision machining and turning capabilities, California Brazing is equipped with a complete, state-of-the-art machine shop offering comprehensive aerospace CNC machining services. Our fully equipped defenseaerospace machine shop is just one part of our component assembly development and turnkey contract manufacturing program, designed to help streamline our client’s various manufacturing processes, while reducing costs, improving quality, and providing quicker turnaround times. Our expert staff works directly with our aerospace and semiconductor clients to develop a customized production plan that meets precise customer requirements. Additionally, we document every aspect of the project from start to finish, ensuring consistently superior results every time we complete an assignment. Our precision machining and turning equipment can work with a broad array of materials, ranging from stainless steel and copper to titanium and aluminum. California Brazing is equipped with only the most advanced machinery, guaranteeing optimal performance, quicker deliveries, and exceptional results. Contact our company today for more information about our aerospace machine shop and specialized semiconductor equipment machining and turning services!

Heat Sinks, Cold Plates and Other Thermal Management Devices, to Aerospace Manufacturing Specs Aerospace CNC machining to the highest standards make us a vendor for critical thermal management devices California Brazing specializes in manufacturing devices for conducting heat into and out of highly specialized systems, from aerospace heat sinks to fuel cell components and everything in between. Our processes are appropriate for a diverse range of industries, including military, defense and aerospace, energy and power, alternative energy, medical, and semiconductor sectors. We work primarily with aluminum, copper and stainless steels in developing cold plates and heat exchangers, which depend on air, gas, and liquid cooling media. We make aluminum cold plates, vacuum brazed cold plates, aluminum heat sinks and other kinds of thermal management devices. Because we’re committed to the quality of our thermal management systems and devices, we are AS9100, and ISO 9001:2008, certified, and can meet a variety of AMS standards. And our in-house precision CNC milling equipment, aluminum vacuum brazing, supply logistics and assemblytest make us a full-service turnkey vendor for aerospace components. To learn how our thermal management systems and devices can work for you, please contact California Brazing today.

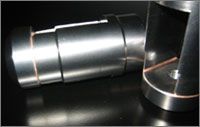

Hydrogen Brazing Services img_3140Hydrogen furnace brazing is a technique where brazing is accomplished in a pure hydrogen atmosphere without flux. This process is used for many alloys, including carbon steel, copper and stainless steel. Hydrogen is used as a reducing agent to remove the metal oxides and as a result, parts are bright and clean after processing. Hydrogen brazing creates durable, flux-free joints of high structural integrity and allows for hardening or heat treating after brazing. The ability of hydrogen to reduce the metal oxides on the surface is determined by temperature, hydrogen gas purity and pressure. Hydrogen furnace brazing is done in a pure dry hydrogen gas atmosphere at a slightly positive pressure in a vacuum furnace. The brazing temperature is dependent on the base metal being joined and the filler metal used in the brazing process. Uniform heating in the furnace allows even complex shapes to be brazed with little distortion. Rigorous temperature uniformity is maintained on the part while being heated, drastically reducing the residual stresses by carefully controlling the heating and cooling cycle. California Brazing specializes in hydrogen brazing and can apply this process to whatever task required, no matter how large or difficult. For a closer look at California Brazing’s hydrogen brazing wherewithal, either contact us today, or file an instant request for quote.

Vacuum Aluminum Brazing vacuum-brazingAluminum vacuum brazing is typically accomplished in a vacuum furnace and used for very high reliability brazing applications. It is a fluxless, clean process where the braze filler material is usually preplaced in the joint and is 100% dense. Vacuum brazing creates a joint with strong structural integrity that will not destruct under intensive pressure. The joint can be machined after brazing, even drilled. Aluminum vacuum brazing is most successful when the part design has a flat surface. This is because pressure needs to be applied in order to break down the oxide layer in the aluminum so that the filler metal can melt and diffuse past the oxide layer into the base metal. In aluminum vacuum brazing, there is no post-braze cleaning. However, more precise machining prior to the vacuum process is required. Below is a typical manufacturing sequence for a Vacuum Brazed Aluminum part. Vacuum Brazed Aluminum Manufacturing Sequence Rough Machine components Chemical Clean Assemble with Braze Alloy Fixture and Braze Braze joint verification Post Braze heat treat Final Machine Braze joint verification Finishing operations (plating) California Brazing’s Director of Aerospace Business Development was utilized as a reference for this definitive article on vacuum aluminum brazing in Advanced Materials & Processes by ASM International, Understanding Key Process Parameters of Vacuum Aluminum Brazing. California Brazing specializes in vacuum brazing of aluminum capable of meeting applicable standards specified by the AWS C3.6 Brazing Specification and AMS 2750 Pyrometry Specification , and is more than able to use this ability to meet whatever challenges our customers present. For further details on California Brazing’s vacuum aluminum brazing services, contact us today, or file an instant request for quote.

Share your thoughts with other customers for California Brazing & Nevada Heat Treating

Add Review