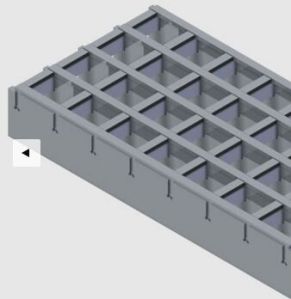

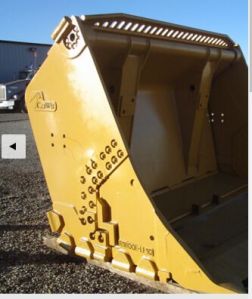

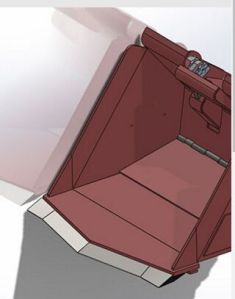

PRODUCT DESCRIPTION CarWil Grizzlies, are an integral part of the muck circuit, are designed and manufactured with longevity in mind. The CarWil Grizzlies custom design meets a variety of applications and sizing requirements and have easily replaceable components minimizing maintenance down time. Designed and built to last, our rugged Grizzlies provide long lasting value to your operations. MARKET DIFFERENTIATOR Grizzlies are used in extreme environments and need to withstand various material, loading conditions, and the damage caused by the hydraulic impact hammers. CarWil has improved the traditional design to relieve and reduce stresses and modified assembly design for ease of maintenance. Designed and built to the highest quality standard, and if so required for extreme conditions, grizzlies may also be heat treated to stress relieve the assembly. High impact and hardness wear bars are added to further extend the life of the grizzly. Designed and built mining tough, many customers choose CarWil grizzlies as their standard for their operations.