Welcome to Colonial Machine

Manufacturer / Exporter / Supplier Of Colonial Machine, plastic jug, Pipe Fitting

-

Year of Establishment

1945

-

Primary Business

Supplier

-

Number of Employees

10-49

Manufacturer / Exporter / Supplier Of Colonial Machine, plastic jug, Pipe Fitting

Year of Establishment

1945

Primary Business

Supplier

Number of Employees

10-49

The image to the left displays a typical jug made from a single cavity blow mold used to produce plastic jugs. The mold has been custom manufactured by Colonial Machine for the liquid storage industry. To begin this project, we first used our vertical CNC milling machinery to rough machine the mold's impression area. We also used our CNC milling equipment to drill waterlines, perform all necessary counter boring and tapping operations, and finish all impression surfaces per client specficiations. Our advanced techology was used to burn any sharp corners - meeting percise .001" tolerances. Formed from 7000 series aluminum, the completed mold measured 6" x 9" x 12". The part also featured steel striker plates and beryllium copper pinch plates. After manufacturing was complete, we preformed glass bead blasting. Satisfying our client's requirements for quality and design, Colonial Machine produced 60 units of this plastic jug single cavity blow mold for the liquid storage industry.

Colonial Machine custom manufactured a series of single cavity injection molds for a client from the material handling industry. The 3D model of this finished product is displayed at left. Used to produce a polypropylene lid, the molds measured 41" x 30" x 15". The units also featured a hi-hard P-20 steel cavity and core, an ejector box, and an Incoe hot runner system. Meeting tolerances as close as .002", we combined our CNC machining, sinker EDM, and grinding operations to manufacture this part. This process included rough machining and finishing the cavity and core block, finishing the waterlines, and drilling all ejector pin holes. In addition, we blended all tool marks and used our advanced Charmilles sinker EDM technology to machine 14 different locations on this part. The core was provided a glass bead finish, while the cavity was given a textured finish. Fulfilling consumer specifications, Colonial Machine has manufactured a great number of this type of mold. Fulfilling our customer’s specifications, we finished the order of 4 molds and shipped to their facility in California within a 6 to 8 week turnaround time. All molds met with absolute customer satisfaction.

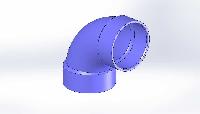

The custom manufactured mold pictured to the left is used to make PVC pipe fittings for the plumbing industry. A client contracted Colonial Machine to fabricate this mold based on a customer-supplied 3D geometry. Our skilled technicians first employed various horizontal and vertical CNC milling machinery to rough machine all impression surfaces and side pockets, as well as counter bore, tap, and drill waterlines to print and machine ejector pin holes. We also produced all side locks and counter pockets, and formed the horn pin clearance. Finally, we finish machined all impression surfaces. After completion, the overall mold measured 56” x 35”, weighed approximately 10, 000 lbs., and possessed various stainless steel cavities and cores heat treated for better wear. The mold produced a 4” diameter 90 degree elbow that satisfied both customer and industry quality standards. Over the years Colonial Machine has produced over 100 molds for a variety of fitting for this customer with this mold being delivered to their facility in Texas easily within their requested delivery time of 10-12 weeks

Share your thoughts with other customers for Colonial Machine

Add Review