Welcome to Custom Machine, LLC

Manufacturer / Exporter / Supplier Of Multi-Axis Precision Machining, Inspection Services, Inventory Management

-

Year of Establishment

1969

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Custom Machine, LLC

Manufacturer / Exporter / Supplier Of Multi-Axis Precision Machining, Inspection Services, Inventory Management

Year of Establishment

1969

Primary Business

Supplier

Number of Employees

50-99

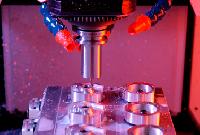

Custom Machine is a high precision machining facility comprised of state of the art CNC Milling, Lathe, EDM and Grinding Machines. With these machining centers we are capable of holding tolerances to within 50 millionths, finishes to 1 light band, turn components up to 22.00" in diameter X 36.00" long and mill components up to 32.00" x 32.00". Our CNC Milling, Lathe and EDM Machines are capable of multi-axis machining with spindle speeds up to 25, 000 RPM. Utilizing these machining centers our team or Engineers, CNC Programmers and Machinists are able to produce components to stringent specifications. We pride ourselves on producing quality components to exacting standards which is evident in our ISO9100:2008 and ISO 13485:2003 certifications.

We perform first piece, incoming, in-process, and final inspections throughout the entire production cycle to ensure the highest quality of every component that Custom Machine manufactures. All incoming material (hardware, raw material, and components returning from an outside process) is thoroughly inspected for material condition, special process specification and chemical composition before it's issued to the machine shop. Our extensive quality department performs a first piece inspection using an advanced Coordinate Measuring Machines (CMM) before each manufacturing process. The finished product is subjected to a 100% final inspection using an advanced Coordinate Measuring Machines (CMM) to ensure that all key characteristics meet the customer's specifications. In accordance with industry and customer standards all first piece, incoming, in-process, and final inspection reports created during the manufacturing process are retained. Our in house testing department performs Non-destructive testing processes such as pressure, vacuum and leak testing in accordance with customer's specifications.

Custom Machine has a diverse and flexible inventory system which is capable of reacting to the demands of our customers. We've worked with systems such as KANBAN, JIT, Kitting, PAC and online procurement systems. Utilizing our machine shop ERP software (JobBoss) we're able to set minimum, maximum and reorder levels for all components and assemblies. If inventory levels reach minimum an automated alert is issued; informing Engineering to release a new production lot to the machine shop for manufacturing. Tracking inventory levels enables us to release economic lot sizes to the machine shop for manufacturing thus reducing our operational expenses and any potential delivery delays to our customers. Custom Machine has the ability to adapt our system to the delivery needs of our customers. In some cases we're able to synchronize our customers system with our system therefore reducing administrative expenses and improving the flow of information. Our onsite warehouse enables us to hold product for release according to the customer's needs

Share your thoughts with other customers for Custom Machine, LLC

Add Review