Welcome to DOMS Incorporated

Manufacturer / Exporter / Supplier Of Full Flow Suction Filters, Suction Filters & Strainers

-

Year of Establishment

1960

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to DOMS Incorporated

Manufacturer / Exporter / Supplier Of Full Flow Suction Filters, Suction Filters & Strainers

Year of Establishment

1960

Primary Business

Supplier

Number of Employees

10-49

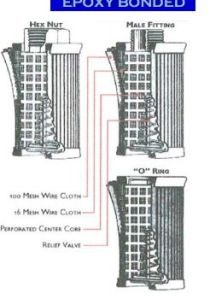

Suction Filters & Strainers with Relief Technical Data Sheet C-104 Valve EPOXY BONDED These filters are identical to the full flow design shown on the Technical Data Sheet C Sheet C 104 These filters are identical to the full flow design shown on the Technical Data Sheet C- 103, except a relief valve has been incorporated into the unit to prevent pump starvation f caused by high oil (fluid) viscosity andor excessive contamination build-up on the caused by high oil (fluid) viscosity andor excessive contamination build-up on the filtering medium filtering medium. The relief valve will actuate when its setting has been exceeded allowing unfiltered oil The relief valve will actuate when its setting has been exceeded, allowing unfiltered oil (fl id) t t th h d li t d ill t h th t th i l t (fluid) to enter the hydraulic system, and will reseat when the vacuum at the pump inlet ( ) y y pp is below the relief valve setting. I i i f dditi l i f ti i th f ll fl th li f l d i Inquiries for additional information covering the full flow or the relief valve design q g filterstrainer will receive immediate attention and reply. filterstrainer will receive immediate attention and reply. When ordering suction filtersstrainers - full flow or with relief valve - use the filter When ordering suction filtersstrainers full flow or with relief valve use the filter f ff f f number as shown in the technical data charts for the applicable filter desired number as shown in the technical data charts for the applicable filter desired. Example: You require a 2 Example: You require a 20 G.P.M. immersible suction filter with a 1 14" N.P.T. female 0GPM immersible suction filter with a 1 14" N P T female connection, 141 micron particle retention and a relief valve set to open at 5"Hg.... connection, 141 micron particle retention and a relief valve set to open at 5 Hg.... Order #22111 FILTERSTRAINER #22111 FILTERSTRAINER.

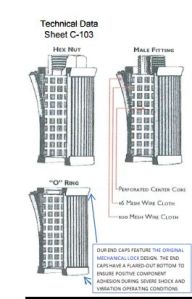

Full Flow Suction Filters and Strainers Technical Data Technical Data Sh t C 103 For Your Hydraulic System Sheet C-103 These suction filtersstrainers are designed for use in oil (fluid) reservoirs and are fabricated with the highest quality materials by thoroughly qualified technicians so with the highest quality materials by thoroughly qualified technicians so optimum optimum performance is assured. f i They provide They provide maximum active filtering area in minimum space maximum active filtering area in minimum space. The filtering medium is The filtering medium is longitudinally pleated and consists of a fine mesh stainless steel wire cloth with a strong 16 longitudinally pleated and consists of a fine mesh stainless steel wire cloth with a strong 16 mesh wire cloth reinforcement. h i l th i f t These units are cleanable. These units are cleanable. They are non-take apart, utilizing epoxy resin to effect a They are non-take apart, utilizing epoxy resin to effect a complete solid bond between the filtering medium perforated center core and end covers complete solid bond between the filtering medium, perforated center core and end covers. Th f t d t l t id i idit t th it d t The perforated metal center core provides rigidity to the unit and warrants satisfactory ti f t application in pressurized reservoirs pp p . They will operate at temperatures from 60o F to +250o They will operate at temperatures from -60 F and are compatible with regular o F to +250o F and are compatible with regular petroleum base hydraulic oils and both aqueous and non-aqueous base fire resistant py q q t l b h d li il d b th d b fi i t t hydraulic fluids. Installation of suction filters and their proper maintenance Installation of suction filters and their proper maintenance minimizes pump failures clogged minimizes pump failures, clogged orifices, sticky valves, and scored cylinders ifi ti k l d d li d by removing solid foreign particles and b i lid f i ti l d materials from the oil (fluid) when entering the hydraulic system at the pump suction line. ( ) g y y pp Maintenance of filters will depend on the type of installation and prevailing operating Maintenance of filters will depend on the type of installation and prevailing operating conditions Cleaning can be accomplished by immersing the filter in a non caustic conditions. Cleaning can be accomplished by immersing the filter in a non-caustic cleaning solvent and rubbing the filter medium surface with a soft bristle brush to l i l t d bbi th filt di f ith ft b i tl b h t g g dislodge the accumulated solid foreign particles and materials.

Share your thoughts with other customers for DOMS Incorporated

Add Review