Welcome to General Wire & Stamping Co., Inc.

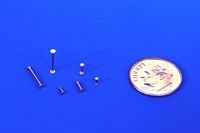

Manufacturer / Exporter / Supplier Of Medium Ligating Clip, Dental Arm, Power Hack Saw Blades, Hearing Aid Bobbin, EJECTOR SPRINGS, Wave Washer

-

Year of Establishment

1974

-

Primary Business

Supplier

-

Number of Employees

10-49

-

Market Covered

Western Europe, Africa, Middle East, Asia, Australia,