Welcome to Helro Corporation

Manufacturer / Exporter / Supplier Of MULTI V TOOL, V BELT TOOL, INSERT PROFILE CUTTER, Form Tools, GEAR HONE

-

Year of Establishment

1969

-

Primary Business

Supplier

-

Number of Employees

1-9

Manufacturer / Exporter / Supplier Of MULTI V TOOL, V BELT TOOL, INSERT PROFILE CUTTER, Form Tools, GEAR HONE

Year of Establishment

1969

Primary Business

Supplier

Number of Employees

1-9

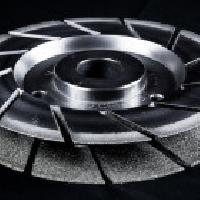

Helro Molecular Diamond Bonded, MDB ®, Multi V rib tools grind significantly longer, cooler, and faster than electroplated grind wheels. Our MDB ® diamond grinding wheels Reduce tooling costs, Improve production process and Increase production rates.

Helro Corporation has over 40 years of global experience providing solutions to the V belt manufacturing industry. Our unique Molecular Diamond Bond, MDB ®, grinding wheels produce precision ground belts for Industrial V, Banded V, Scooter, ATV Snowmobile belts. Our experience includes grinding tensile cord materials of aramid, nylon, or polyester and EPDM rib materials with fiber loading of aramid, nylon, cotton, or polyester. We work with manufactures to optimize your belt profile, cord finish, and fiber exposure to produce products that exceed your customers’ expectations.

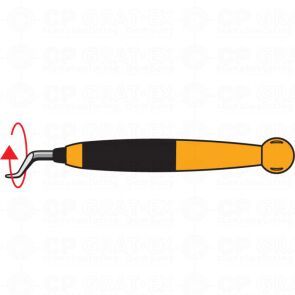

Helro Insert Profile Tools reduce belt profile cutting tool costs 40%, tooling inventory 50%, logistics costs 90%, and delivery lead times from 6 weeks to 2 weeks. Our Insert Profile tools utilize a patented design to attach the insert to the cutter body that allows two uses per insert. This design creates the ability to remove the worn inserts, flip the insert and reinstall it for a second use.

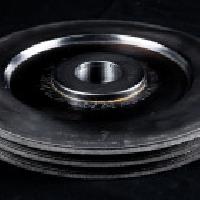

Helro Molecular Diamond Bond, MDB ® form grinding wheels perform significantly longer, cooler, and faster than electroplated grind wheels. Our MDB ® diamond grinding wheels Reduce tooling costs, Improve production process and Increase production rates.

Helro Corporation has over 40 years of experience providing honing solutions to the gear manufacturing industry. Gear hones are available in Tungsten Carbide or with our unique MDB ® Diamond abrasive coatings. Helro gear hones operate on your existing honing or shaving equipment to correct distortion caused during heat treat of gears. Our gear hones can reduce noise in gear assemblies by improving oil retention, and eliminating nicks and burrs that occur in the manufacturing process. Our engineering team can help design a hone for your application or recondition your existing hard hones. The Helro Tungsten Carbide and MDB ® Diamond coatings are compatible with many existing honing tool substrates.

Share your thoughts with other customers for Helro Corporation

Add Review