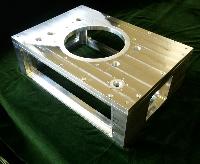

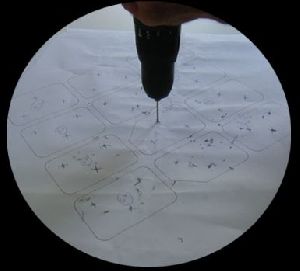

At Hirsch Machine, Inc., we have been providing high quality machining services since 1981. We have an assortment of CNC and manual machines that can manufacture nearly any type of metal or plastic part. Our CNC machining centers can accurately and efficiently produce parts as large as 10" x 20' x 40" holding tolerances as close as .001" on locations and .0002" on sizes. Our CNC turning centers make round parts as large as 8" in diameter and 20" long. We also have multi axis lathes that can simultaneously turn and mill eliminating many secondary operations. These CNC lathes can machine nearly any metal or plastic hold tolerances as close as .0002". All lathe and mill operations are supported by our inspection staff to insure correct high quality parts. Hirsch Machine Inc. works with nearly all metals and plastics, for example, aluminum, brass, bronze, copper, steel, stainless steel Inconel alloys as well as ABS, acetal, acrylic, nylon, PDF, polyethylene, polypropylene, PVC, PTFE, and Vespel. Our high tech equipment works to uncompromising levels of accuracy, with closest tolerances of up to +- .0001” available. We also provide consulting, design, custom engineering, inspection, and testing services to assist at every level of product development and manufacturing. The efficiency of our operation is also demonstrated by our automation that enables us to run 2 to 3 shifts of lights- out manufacturing. We specialize in short to medium sized runs of up to 1, 000 pieces, with lead times averaging around four weeks. Special expedites are available upon request.