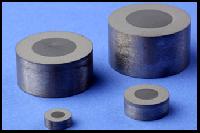

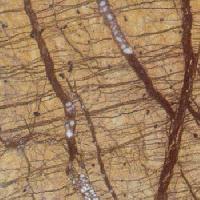

Excellent performance. Consistent quality. Outstanding value. Your customers want a drill bit that will get the job done every time. You want a PDC cutter that’s in it for the long haul. With IDS PDC cutters, you can make it happen without digging into your bottom line. IDS PDC cutters are produced from start to finish under the same roof and undergo a rigorous, but noninvasive inspection process, all in compliance with ISO 9001:2008 quality standards. In the field, they have been proven in a variety of drilling conditions on every continent on the planet. IDS offers three categories of PDC cutters: High Impact Toughness PDC- Premium PDC cutters with excellent impact resistance and high abrasion resistance. These cutters are designed for tough, uneven drilling conditions, combining superior resistance to chipping and cracking with the abrasion resistance necessary to ensure a long cutter life. High Abrasion Resistance PDC- Premium PDC cutters with excellent abrasion resistance and high impact resistance. These cutters are designed for drilling conditions, where high wear and cutter rounding are common. General Purpose PDC- High-value, mid-range performance, general purpose PDC cutters with high impact resistance. These cutters are used in a wide variety of applications, including: -Oil and gas PDC bits as face, gauge, and backup cutters -PDC bits for geothermal drilling -PDC bits for water well drilling -PDC bits for directional drilling -Reaming tools -Core bits -Bearing elements We’re also committed to research and development, meaning the newest IDS PDC cutter is already in the works. And if you need cutters with a unique or unusual shape or properties, we can provide those as well.