Welcome to Involute Gear

Manufacturer / Exporter / Supplier Of Gear Roll Testers, Master Gears, Gear Honing, Axis-CNC Hobbing Machine

-

Year of Establishment

2009

-

Primary Business

Supplier

-

Number of Employees

1-9

Welcome to Involute Gear

Manufacturer / Exporter / Supplier Of Gear Roll Testers, Master Gears, Gear Honing, Axis-CNC Hobbing Machine

Year of Establishment

2009

Primary Business

Supplier

Number of Employees

1-9

In 2009, Involute Gear and Machine Company purchased all equipment, machines, supplies, materials, gages, and engineering drawings for the manufacturing of all types of Red Ring Hone Tools and Honing Compounds.All gear honing machines are now in our Chesterfield, Michigan facility and are fully operational and ready to serve you. Gear honing is a hard gear finishing process that was originally developed and patented by National Broach & Machine Co. The process can be effectively applied to hardened, external and internal spur or helical gears up to 180-in. diameter to: 1. Improve the sound quality of shaved, hardened gears by removing nicks and burrs; and making minor improvements in involute, lead, tooth spacing, P.D. runout and surface finish. 2. Prolong wear life and increase load-carrying capacity of ground, hardened gears by improving surface finish to a point where up to 80-percent of surface contact can be achieved with the mating gear. 3. Salvage hardened gears with oversize teeth, runout from excessive heat treat; distortion, or damaged or nicked teeth. The gear honing process uses abrasive-impregnated honing tools in the form of a helical gear. These tools are made with a variety of abrasive grits in two honing types and one polishing type to produce surface finishes down to the 4 to 6-mu range. The tools are mounted on special honing machines in crossed-axes, controlled-mesh relationship with the gear to be honed. During the honing cycle, the work gear is run with the honing cycle, the work gear is run with the honing tool at speeds of approximately 600-ft. per minute. The honing tool is traversed back and forth across the gear face, and direction of rotation of the honing tool is reversed at each end of the stroke. Particles removed by honing are carried away with conventional honing oil. Four different methods are used to apply pressure between the work and honing tool, which normally should not exceed 40-lb. The honing machines are equipped with tilting table or air feed arrangements which can be either locked in position to provide a pressure control method, or pressurized with and air cylinder to provide a constant-pressure method.

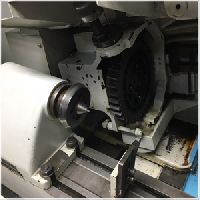

Model KT50 6 Axis-CNC Hobbing Machine Suitable for Hobbing Small Sized Planetary Pinions A Compact and Complete Dry Cut Hobbing Machine (Wet Cut Hobbing Machine is optionally available) Max. Workpiece Diameter : 50 mm Max. Module : 2

Master Gears OSK designs and manufactures high-accurate master gears for double flank gear rolling testers

GTR-4 is a double flank gear rolling tester for fine pitch gear or small gear used for the wide range of instrument such as measuring equipment, clock, camera, computer peripheral equipment, copying machine and audio device all over the world.

Share your thoughts with other customers for Involute Gear

Add Review