Welcome to JENTEK Sensors, Inc.

Manufacturer / Exporter / Supplier Of the JENTEK Eddy Current Array Tester, JENTEK Core Competencies, Nondestructive Testing, Eddy Current Testing

Welcome to JENTEK Sensors, Inc.

Manufacturer / Exporter / Supplier Of the JENTEK Eddy Current Array Tester, JENTEK Core Competencies, Nondestructive Testing, Eddy Current Testing

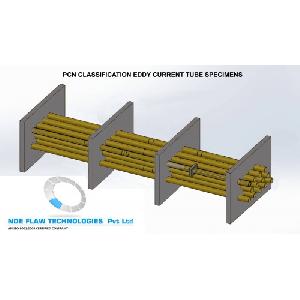

• Engine Component Inspection • Blades, disks, IBRs, holes, etc. • NDT of Complex Structures (per ASTM E2884-13 Standard Guide for Eddy Current Testing of Electrically Conducting Materials Using Conformable Sensor Arrays, ASTM International, Book of Standards, Vol. 03.03.) • Surface breaking and subsurface cracks • Hidden corrosion • Coating Characterization without need of expensive custom calibration standards (per ASTM E2338-11 Standard Practice for Characterization of Coatings Using Conformable Eddy-Current Sensors without Coating Reference Standards, ASTM International, Book of Standards, Vol. 03.03.) • Complex Shaped Surfaces • Firtree slots in engine disks, fillets in aircraft structures, etc. • MaterialsProcess Quality Characterization

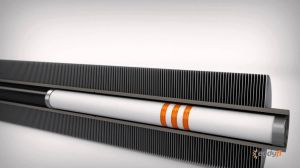

Nondestructive Testing for SCC Crack Mapping and Depth SizingMWM-Array Scanners for SCC Detection through Coatings Wide-area scanning arrays for preliminary screening of SCC through coatings (coal tar wrap, epoxy, etc.) Scan rates over 20 sq. ft.min (1.86 m2 ) using JENTEK’s GridStation 8200 instrumentation MWM-Array Scanners for High-Resolution SCC Crack Mapping & Sizing High-throughput C-Scan imaging of discrete cracks andor SCC colonies Conformable MWM-Array eddy current sensors configurable for wide range of pipe diameters Minimal surface preparation requirements (not affected by coatings, moisture and dirt) Crack Depth Software Module – JENTEK GridStation Software Rapid conversion of MWM-Array response into depth measurements Automatic crack interaction capability Electronic storage and retrieval of measurement data (as potential MPI replacement) Microsoft Windows™ environment with GridStation software for quick and easy report generation

The Leader in Eddy Current Testing PerformanceFast Corrosion Imaging for Piping, Vessels & Column Inspection Light weight, ideal for rope access crews Manual scanner with encoded C-scan imaging JENTEK Sensors recommends the non-integrated system (IN8200) for field services and the integrated system for special applications in the laboratory, or in certain situations where having an integrated version is preferred.

JENTEK Founded in 1992 • JENTEK Core Competencies Model-Based Inverse Methods, Electronics Design, NDTNDENDI, SHM • JENTEK focus is improving safety and quality while delivering high ROI • MWM-Array • Winner FAAATA “Better Way” Award • National Tibbets Award • ASNT Best Paper Award • U.S. Navy Phase III Commercialization Award • FAA approved for some engine inspections • U.S. Navy Standard practice for engine inspection • Implemented on Space Shuttle Leading Edge at NASA KSC • Proven to provide improved inspection performance using model based multivariate inverse methods (MIMs) • GridStation Software and HyperLattice based MIMs • Intuitive operator interfaces • Inherent self-diagnostics • C-Scan imaging of multiple properties simultaneously (e.g. first and second layer corrosion, or coating conductivity and thickness) • Convenient procedure and data management

Share your thoughts with other customers for JENTEK Sensors, Inc.

Add Review