Welcome to Miller Precision Industries, Inc.

Manufacturer / Exporter / Supplier Of Studded Fastener, Compressor Head Component, Valve Cover

-

Year of Establishment

1988

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to Miller Precision Industries, Inc.

Manufacturer / Exporter / Supplier Of Studded Fastener, Compressor Head Component, Valve Cover

Year of Establishment

1988

Primary Business

Supplier

Number of Employees

10-49

The primary use of these fasteners for the military varies. These threaded inserts are used to fasten armor plate to expeditionary fighting vehicles, mount electronic equipment to the inside of aluminum structured vehicles, and anything that is has an aluminum structure that you would need to mount something to. These were used in a watertight application that they needed to mount armor plate on the outside of a vehicle, and mount seats and equipment on the inside of the vehicle.

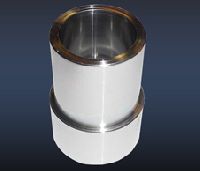

Parts used to Efficiently & Digitally Control the system pressure in HVAC Compressor HeadsAt Miller Precision Manufacturing Industries, Inc., our valued combination of technology and hands-on expertise allow us to manufacture close tolerance components that meet an elevated standard of quality. When a client in the HVAC industry was having difficulty finding a supplier that could hold ± 0.0005" tolerances while maintaining high quality surfaces, they approached us to tackle this job. Used to digitally control system pressure in HVAC compressor heads, we constructed the components highlighted here from pre-hardened 4140HT steel as well as high-strength 6061-T6 aluminum. Our multi-axis Swiss lathe allowed us to create the compound geometries with remarkable accuracy and repeatability all from a single set up. We used sophisticated measurement devices as well as precision calibrated air, ring, and plug gauges to check the consistency of the surface and confirm the dimensions were within tolerance. When completed, the parts measured from 0.875" to 1.25" and featured 12 Ra to 64 Ra surface finishes. To protect these sensitive components, we used an ultrasonic cleaner to remove all contaminants without harming the substrate, applied a rust inhibitor, and packaged them in custom shipping trays and boxes. After successfully completing the initial pilot runs, we quickly ramped up to full production. To learn more about this project, please see the table below, or contact us directly for more information about our precision manufacturing capabilities.

Product Description This cover is used to protect the valves on a forklift. Capabilities AppliedProcesses Primary: Painting 2 Operation Horizontal Milling Secondary: Pressure Testing Product Packaging Equipment Used to Manufacture Part MA-400HA Okuma Horizontal Machining Center Expertise Figured out paint process to customer specs, designed machine fixturing.

Share your thoughts with other customers for Miller Precision Industries, Inc.

Add Review