Welcome to Paramount Tube

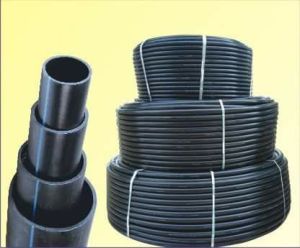

Manufacturer / Exporter / Supplier Of Custom Shapes, Extruded Tubing, Vulcanized Fiber, Plastic Tubing, PAPER TUBING, Phenolic Paper

-

Year of Establishment

1990

-

Primary Business

Supplier

-

Number of Employees

100-199