Welcome to Phelps Industries, Inc. US

Manufacturer / Exporter / Supplier Of Permanent Installation, Portable Landfill Tipper, Container Loader, Corn Hopper, Power Units

Welcome to Phelps Industries, Inc. US

Manufacturer / Exporter / Supplier Of Permanent Installation, Portable Landfill Tipper, Container Loader, Corn Hopper, Power Units

Phelps Industries, Inc. offers tilters that can be designed to either load or unload 20 to 40 foot intermodal containers. These can be set up to work with flatbed trailers or a transfer car rail system. The bulkhead retainer, with or without a discharge manifold, can be used to interface with your takeaway system. Our systems are not a "one size fits all". We will modify our equipment to suit your systems and materials handled. Tilters can be set up to elevate from 30 degrees to 65 degrees. Phelps' tilters may be permanently affixed to a concrete foundation or equipped with a sub-frame for semi-portable operation on a concrete slab. Tilters may be equipped with a scale system for continuous weighing. Bulk loads delivered in intermodal containers are a step to the future, and we're here to help.

Phelps Industries developed the Corn Hopper to handle bulk deliveries of raw corn from self-dumping trucks. This receiving hopper is available in a variety of holding capacities and discharge rates. It can be custom built to suit your receiving tonnage and unloading needs. A hydraulically operated reciprocating floor moves the corn to your current conveying system. This transport system provides easy viewing, a clean surface and an efficient mode of bulk unloading. A simple concrete slab and a 12" high ramp is all that is needed in one type of installation. Your foundation can also be constructed so the unit does not have to be raised for maintenance. The corn hopper is portable in that it can easily be picked up by two forklifts and set on a flatbed trailer for transfer to another corn receiving station. Corn Hoppers can also be used in combination with a Phelps TruckTrailer Dumper. This application works well with semi-trucks that are not self-dumping.

Phelps Industries has been manufacturing industrial power units for 25 years. Our power units are designed to fit any specific need. Systems can be designed for simple actuation or multiple operations. Standard units are fabricated from 14" A-36 steel plate, and are internally sandblasted. Each unit has a bolted flange removable type lid. JIC standards are also incorporated into every reservoir. These standards include an internal baffle, oil level gauge, manway access, fillerbreather caps or filters, condensation drain and magnetic rod. Various horsepower and GPM ranges are available for all power units. We also have basically any size reservoir you may need, from 60 gallons up to 2, 000 gallons. Dissipation of heat is always a concern in a hydraulic power unit, so we design and size the reservoir with this factor in mind. Other factors involved in tank size are GPM output and displacement required for full actuation. We use totally enclosed fan cooled high efficiency C-face motors on all units. C-face motors are used with a bell housing type coupling guard where possible. Fiberglass coupling guards are used on standard motors with flex couplings. Driven pumps are either fixed or variable displacements. This depends on each application. Most units have the pumps and associated componentry atop the reservoir, but flooded suctions are available.

The Phelps Low Profile Landfill Trailer Tipper is designed for over-the-road transportation, when several major components are unpinned and removed comprising a second trailer load. Tipper is designed to raise itself in front for coupling to a trucktractor or converter dolly for relocation in the landfill. Time required for in-the-cell relocation is approximately fifteen minutes. This ease of movement is critical to landfill operation to save the costs of long distance pushing of materials away from tipper. All portable landfill tippers utilize a self-contained diesel powered hydraulic power unit.

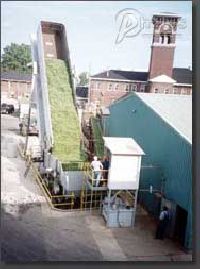

These models are set on a poured concrete foundation at your plant. We manufacture a variety of different models. Each model is determined by the length and its tilt angle. Our assembly mission is to build a strong rigid platform. This is why the dumper is fabricated 10'-0" wide by the desired length. This means one large fully welded deck shipped to you. Our standard lengths are 35'. 40', 45', 50', 60', 65', 70' and 75' which indicates the amount of useable deck. Standard tilt angles are 36o, 45o, 55o, and 63o. The product you are handling will determine the needed tilt angle. This is directly related to the angle of repose of the product. We will be happy to consult with you regarding this, given our experience. If you would like to know more about specific engineering data, please call or fax in your inquiry. We will discuss your application and the design criteria required. Keep in mind all parameters of your application, length of trailer or truck, gross weight, product handled, and if you would like to back on or drive through the unit. We look forward to designing and supplying the best engineered product to accomplish your task.

Share your thoughts with other customers for Phelps Industries, Inc. US

Add Review