- Delivery/Turnaround Time7-8 Weeks (Production)

- Delivery LocationUSA

- Product DescriptionCustom manufacturing of child cochlear implant carrying cases.

- Volume700 per Month

- Standards MetCustomer Functional/Visual Specifications 2D QA Drawings FDA ISO 9001 & 13485

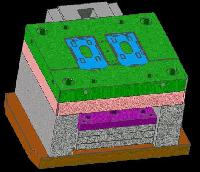

A customer in the medical industry contracted ProPlas Technologies to create a custom carrying case for their Cochlear implant unit. To protect the $45, 000 implant, the case needed to be water-resistant and durable as well as contain multiple compartments for the wearable receiver electronics, batteries and accessories. Our experts worked with the customer to manufacture the case, detailing the final refinements in a 3D CAD models in SolidWorks. The case shell was created with thermoplastic elastomer (TPE) overmolded on ABS, and polyetherimide (PEI), utilizing our 30, 65, 85 and 110 ton electric injection molding machines to form the materials in the eight total plastic parts in the assembly. Several tight tolerances of ±0.002" were met during the injection molding step. As an added design feature, we were able to integrate a desiccant compartment into the construction for moisture absorption. Fourteen total components were sourced, assembled and labeled as specified by the customer. A comprehensive testing and inspection protocol including drop testing, visual, functional and dimensional testing were carried out to ensure product quality and integrity. The completed carrying case measured 7 ½" in length, 4 ¼" in width, and 1 ¼" in height. The injection molding and assembly are conducted under the ISO 9001 and 13485 standards for medical devices in our FDA registered facility. Turnaround time for this project was 15 weeks for engineering and tooling and production orders take as much as 7-8 weeks due to purchased component lead-times. 700 unitsmonth are produced, specially packaged and shipped to our customer for kitting and fulfillment throughout the USAWorld. For more details about custom molding and assembly projects, or our other recognized capabilities available please see the table below or contact us directly.