Welcome to Stern Companies, Inc.

Manufacturer / Exporter / Supplier Of Rotational Molding, Injection Molding, blow molding, thermoforming

-

Year of Establishment

1995

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Stern Companies, Inc.

Manufacturer / Exporter / Supplier Of Rotational Molding, Injection Molding, blow molding, thermoforming

Year of Establishment

1995

Primary Business

Supplier

Number of Employees

50-99

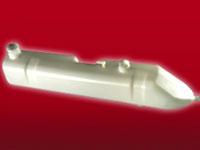

Stern Companies total commitment to our customers goals has included the performance of quality rotational molding services in a timely and cost-efficient manner. Rotational molding is a low-pressure process and the strength required from the molds is minimal. This results in its ability to produce large or complex parts on short notice, using inexpensive molds. Due to the low tooling cost, rotational molding is ideally suited for producing prototypes and small or large quantities of production parts. Rotational molding tends to produce an increasing wall thickness on outside corners of parts, which gives the process a distinct advantage. We have the technical ability and technology needed to execute intricate contours, undercuts, molded-in inserts and double walls. Our product expertise applies to everything from specialty tanks to storage containers as well as kayaks, agricultural products and boat consoles. Our Rotational Molding Facility equipment includes: Ferry RotoSpeed 370 - 4 arm turret Ferry RotoSpeed 280 - 4 arm turret Ferry RotoSpeed - 3000 - 2 arm shuttle Ferry RotoSpeed - 2600 - 2 arm shuttle Raw, WIP and finished storage comprising of 21, 450 sq. ft. Located in a 49, 350 sq. ft. facility At Stern Companies, we take quality seriously. We are ISO ASQ Certified and meet SAE ASTM Standards. Stern has the capacity to handle your project, large or small.

Stern Companies provides quality injection molding services for customers that are looking for small or large parts in either simple to complex geometric shapes. We are dedicated in finding the right molder for your project. We partner with manufacturers who use the latest technologies to produce parts, monitor quality and ensure repeatability. We are happy to work on projects from low volume batches to the multi millions of components. Stern Companies recognizes the importance to our customers to optimize the functionality of their components while achieving and maintaining lower production costs. We provide the expertise, experience and care with the identification and selection of the most effective material, a key factor in realizing higher performance and maximum cost efficiency. We utilize a wide range of plastic materials, such as PEEK, PVC, Polyethylene’s, Polypropylene’s, Nylon’s, ABS, Acetal, Styrene, TPE. Whether you’re starting a new plastic molding project or need us to take over a job in progress, Stern Companies can meet the most demanding specifications and performance requirements in molding plastic. At Stern Companies, we take quality seriously. We are ISO ASQ Certified and meet SAE ASTM Standards. Stern has the capacity to handle your project, large or small.

Stern Companies offers a wide range of custom blow molding services and can provide innovative solutions based on our industry expertise and years of experience. Specifically, we can offer injection, co-extrusion, multi-layer and double-wall panel blow molding to produce parts that are stronger, lighter and affordable. In short, our blow molding services can offer significant competitive advantages in certain applications. We are dedicated in finding the right molder for your project. We work with a variety of materials, such as ABS, TPE, HDPE, LDPE as well as many others. Stern offers capabilities needed for metal and plastic molded-in inserts. When it comes to sizing, we can handle parts as light as 2 oz. and weighing up to 60 lbs. In addition, we have the equipment required for diameters to 24”, widths to 50” and lengths to 78”. We understand our customers’ needs, which is why we provide a broad range of value added services, from CNC robotics to logistical support. At Stern Companies, we take quality seriously. We are ISO ASQ Certified and meet SAE ASTM Standards. Stern has the capacity to handle your project, large or small.

Stern Companies performs a variety of quality thermoforming services for the recreational vehicle, sporting equipment, medical, food packaging and other industries. In order to deliver the specific quality and performance characteristics as well as the cost efficiencies required by our customers, we offer vacuum forming, twin sheeting, pressure forming and multi-layer twin sheet. We work with a range of materials, such as PVC, ABS and polystyrene, and apply the most suitable high-gloss and paint film coatings. We are dedicated in finding the right thermoformer for your project. We have access to the equipment required to manufacture components that are up to 12’ long, 8.5’ wide and up to 48” deep. In addition, we can handle gauges of .060” to .500”. Our value-added services include CNC and 5-axis trimming, engineering, assembly and blanket ordersdrop ship. In today’s competitive environment, we pass along the efficiencies gained through our various management systems such as lights-out manufacturing and Certified Quality Engineering. At Stern Companies, we take quality seriously. We are ISO ASQ Certified and meet SAE ASTM Standards. Stern has the capacity to handle your project, large or small.

Share your thoughts with other customers for Stern Companies, Inc.

Add Review