Huawei M750 Cdma Mobile Phone

CCCP Distributio...

Samsung R720 Cdma Mobile Phones

CCCP Distributio...

Hms 1& 2 Scrap

MJ Enterprise of...

Urea Granules

MJ Enterprise of...

full cream milk powder

MSS Associates L...

Coking Coal

Delta Equities L...

Urea Powder

Delta Equities L...

90 % Aluminum Wire Scrap

Fair Trade LTD

Canned Tomato Paste

Fair Trade LTD

Edible Lactose

MSS Associates L...

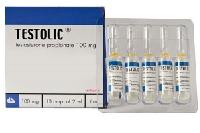

Testolic Testosterone Propionate 100mg 2ml

Lawson INC

PENEGRA 100mg

Lawson INC

Mining Machine Spare Parts

Median Tax Deed ...

Black White Stripe Cabana Tent

One Source Event...

Bordeaux Vase

One Source Event...

double-action Robatech piston pumps

Robatech Canada

Jetting heads reactive adhesives

Robatech Canada

nuts

Fasteners Unlimi...

Sockets

Fasteners Unlimi...

Safeline Metal Detector

Frain Industries

Laars Heating System Company Boiler PWO400CN22CNAC...

Frain Industries

amba haldi

Natural Indian H...

Andrographis Paniculata

Natural Indian H...

Coast Grayson Sheesham Dining Bench

Furniture wareho...

USA largest searchable B2B Marketplace and Business Directory providing a trading platform for USA Jewelry Suppliers and Buyers. We have a huge database of USA Jewelry Manufacturers Exporters and Suppliers.