Welcome to Surtronics, Inc.

Manufacturer / Exporter / Supplier Of Silver, Electropolish

-

Year of Establishment

1965

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to Surtronics, Inc.

Manufacturer / Exporter / Supplier Of Silver, Electropolish

Year of Establishment

1965

Primary Business

Supplier

Number of Employees

10-49

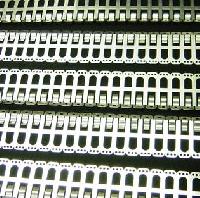

Silver electroplate can be applied utilizing either rack fixture or barrel plating technologies. Typically a silver-plating specification will specify a matte, semi-bright, or bright finish with or without a chromate post treatment to improve tarnish resistance. Plating specifications also designate the base coating to be applied under the silver plate. The thickness of coating can range from 1 micron for short-term shelf life and solderability, to 10 microns for thermo compression bonding and die attachment, and up to 40 microns for severe wear resistance applications. Other factors addressed in silver-plating specifications include the purity of silver, hardness, conductivity, and solderability requirements and methods for testing adhesion. Plating with Silver provides performance, strength, and functionality. Silver plating provides the critical benefits of solderability and electric conductivity for use in high tech applications. Plus, silver plating is quite resistant to corrosion and does not oxidize easily, but will form a surface tarnish of silver sulfide. Of all the metals, Silver is the best conductor of electricity. In electroplating, silver is primarily used for industrial applications: electrical connectors & contacts, batteries, medical instrument, semiconductor, telecom, pharmaceutical & automotive industries. Silver is harder than gold but softer than copper. Pure silver, (chemical symbol Ag) has a brilliant white metallic luster. It is a little harder than gold and is very ductile and malleable. Pure silver has the highest electrical and thermal conductivity of all metals, and possesses the lowest contact resistance. It is stable in pure air and water, but tarnishes when exposed to ozone, hydrogen sulfide, or air containing sulfur

Polishes, Deburrs, Levels, Cleans Steel, and Stainless Steel. The process removes high points on metal surfaces, giving the surface a high luster. The process produces a unidirectional pattern that is both stress-and occlusion-free. Electropolishing is ideal for medical, pharmaceutical, semiconductor, and food processing equipment and parts. The combination of no directional lines and a surface relatively devoid of hydrogen, results in a hygienically clean surface where no bacteria or dirt can accumulate. Rack Only

Share your thoughts with other customers for Surtronics, Inc.

Add Review