Welcome to Tampa Grocery

Manufacturer / Exporter / Supplier Of Custom CNC Plastic Trimming, Plastics Pressure Forming, Custom Fabrication of an Acrylic Stand, Shipping Trays, Custom Thermoformed Styrene Trays

Welcome to Tampa Grocery

Manufacturer / Exporter / Supplier Of Custom CNC Plastic Trimming, Plastics Pressure Forming, Custom Fabrication of an Acrylic Stand, Shipping Trays, Custom Thermoformed Styrene Trays

Our full service forming capabilities allow us at Lane Plastics to provide our customers with innovative solutions to their manufacturing needs. Our capabilities including thermoforming, pressure forming, and drape forming, which can be used to create everything from grocery food trays, to lighting fixtures, and point-of-purchase display units, just to name a few. We work with plastic materials such as ABS, acrylic, PETG, polycarbonate and Styrene, as well as many others. Our facility and equipment are state of the art, automated and PLC controlled that can produce precision formed plastic products up to 105” in length, and 62” in width, .500” in thickness, all while maintaining tolerances of ±.030”. To learn more about our custom thermoforming capabilities and get the specifics please see below. You can also reach out to us directly for more information on the expertise we can offer your company.

At Lane Plastics we provide precision CNC plastic trimming services, with 5-axis capabilities. Our processes can maintain tolerances to ±.005”, with components up to 120” X 74” X 36”. We work with a wide range of plastics, including ABS, foam, nylon, acrylic and fire-retardant materials among many others. In addition we also provide services such as assembly, decorating, engraving, hot stamping, mold design, and pad printing. We specialize in prototypes and low-volume runs, but also have the capacity to take on high-volume production. Our experience and expertise allows us the flexibility to offer rush services or to develop a custom delivery schedule, it also allows us to meet a wide array of industry standards. We are a customer centric company providing personalized customer service to clients in various industries, for a wide range of applications. To learn more about our CNC plastic trimming capabilities please see below and contact us directly.

A client in the medical industry approached Lane Plastics in need of a thermoformed styrene tray to hold injection molded medical parts. The tray was to be used as a parts holder in their manufacturing process. The customer supplied us with sample parts which allowed us to depict the actual use of the tray. Based on our usage depiction, our team generated CAD drawings, and created a prototype that employed all of the necessary features. Using our thermoforming capabilities we created the tray using white styrene with a smooth finish. The finished tray was 15" long, 6.75" wide, and 58" high, and maintained tolerances of ±.03". Regular part inspections were performed throughout the manufacturing process, to ensure that a high level of quality was maintained.

An auto parts manufacturer contacted Lane requiring a custom thermoformed shipping tray constructed of ABS. The client had an existing product that they wanted to replace with a reusable item made from recycled plastic. It had to be environmentally friendly, and be able to stand up to hard use. They provided us with specific dimensions for the piece, which was designed to protect the automobile components that they manufacture. The trays needed to capture the banding straps that would fasten the stacks of loaded parts trays, and include stacking and nesting features to save space when empty. The stackable design also required that the top and bottom sections fit without shifting. We purchased recycled ABS, and thermoformed the top and bottom sections, as well as thermoforming their logo onto the product. A haircell texture was also applied to resist scuffing. We then precision CNC routed both sections, and submitted the first part to the customer for approval. During the production run we performed fit tests and inspections to ensure quality.

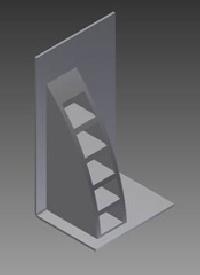

A customer in the display industry approached Lane Plastics in need of a custom fabricated acrylic stand. The product was to be used to display hearing aids. As a family-owned business passionate about serving our customers, we worked closely with this client throughout the project. Lane Plastics designed a stand to look like and fit the customer's art work and engineered the stand for acrylic fabrication. In order to have consistent and high quality parts the base, side walls and shelves were designed to go together with a tongue and groove feature in conjunction with a solvent bond. There was also a hinged door on the back to access the product. Using pre-printed, white acrylic and clear PETG, we CNC routed the parts according to the CAD file, drape formed them in our ovens using a forming pan, line bent the backer and base, and assembled the display with solvent bonding. Our state of the art equipment included a CNC router, thermoformer, and linebending heaters. The custom acrylic stand is 8.000" long, 6.190" wide, and 14.000" high, fabricated to tolerances of +- .03" After producing a prototype part and receiving approval from the client we promptly delivered the production run to our client, whose needs met, and expectations were exceeded.

Share your thoughts with other customers for Tampa Grocery

Add Review