Welcome to Ultimate Hydroforming, Inc.

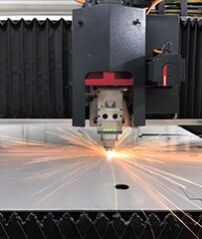

Manufacturer / Exporter / Supplier Of Tubular Hydroforming, Deep Draw, Pulleys Control Arms, Laser Cutting

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Ultimate Hydroforming, Inc.

Manufacturer / Exporter / Supplier Of Tubular Hydroforming, Deep Draw, Pulleys Control Arms, Laser Cutting

Primary Business

Supplier

Number of Employees

50-99

Small to Large Assemblies Robotic and Manual Weld Capabilities Migtigresistance welding Spot welding and hanging spot welding Full CMM Inspection of assemblies Vacuum Brazing Engine Cradles, Shock Tower, Pulleys, Control Arms

We offer deep draw and unusual forming of most materials, through hydroforming and other methods. Achieve greater depth than diameter Unusual forms while holding tolerance Prototyping available to see if-in-fact possible

Tubular Hydroforming is gaining popularity in several markets for its track record of producing better quality components at a lower cost. Some of the benefits of Tubular Hydroforming over conventional tubular structure forming and welding include: Our automated AP&T Tubular Hydroforming unit uses state of the art controllers, is rated at 1200 tons with pressures of up to 4000 bar and can handle part lengths of up to 42 inches. High Precision maintaining constant wall thickness Piercing during the HF process Complex parts produced with less tooling expense Increased product design flexibility and part strength Lower weight because of less material used High bending strength and torsional stiffness Increased overall quality and structural intent

Two NTC TLM614 3300 watt 5 Axis Laser Three NTC TLM610 3300 watt 5 Axis Laser One NTC TLM610 2500 watt 5 Axis Laser One NTC TLV-510 D 3300W 3-Axis Laser Tebis programming to cut lead times and improve accuracy

Share your thoughts with other customers for Ultimate Hydroforming, Inc.

Add Review