- MaterialTitanium

- Material FinishAnodize for Titanium

- Tightest Tolerances±.0005"

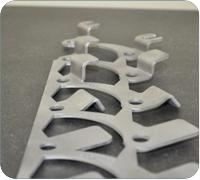

Making use of our EDM machining capabilities, Wire Pro manufactures titanium fracture plates used within a facial implant application. These titanium components are specially made for a client in the medical industry, operating to a tolerance of ±.0005” in keeping with the close precision required for such an application. Pieces are EDM machined to minimum lengths as small as .300” and widths of .100”, with material thickness as thin as .024”. On the larger end of titanium fracture plates that we EDM are pieces with lengths to 8.00”, widths to .250”, and a maximum thickness of .125” in this application. Once the EDM machining process is completed, the component undergoes a tumble deburr operation to ensure a smooth, uniform surface free of sharp edges or ridges. Finally, the piece receives an anodized finish. Our CAD and CAM design services are used throughout the production of each titanium piece, designing and manufacturing unique features which can include round or irregularly-shaped notches and holes used for fastening or surface stress relief. Our client’s order runs between 100 and 5, 000 of these pieces each year, and Wire Pro meets ISO standards in the EDM manufacturing of this product.