- MaterialBillet Aluminum

- Overall Part DimensionsLength: 6.125" Width: 5.5" Height: 7"

- Tightest Tolerances±.0003"

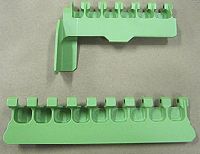

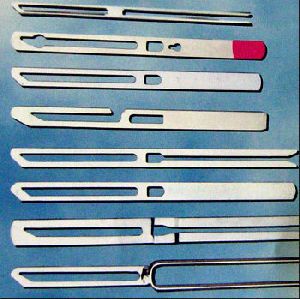

A military manufacturer required sophisticated machining and assembly of an extruded aluminum end fitting used in the aerospace industry. The fittings, made to military specifications, were 6.125" long by 5.5" wide and 7" high. To manufacture the end fittings, Aljo-Gefa Precision Manufacturing LLC. used a CNC horizontal milling process that consisted of drilling, boring, profiling and pocketing. Final assembly process included press-in bearings, riveting, and helicoil thread inserts that increase thread life even after repeated assembly and disassembly. The customer order for this product consisted of 15 to 30 parts to be produced monthly. Each fitting had to be anodized, primed, and painted before being placed in customer specified packaging, one per box. To learn more about this project, or to learn how Aljo Gefa can meet your needs, see the table below or contact us directly.